News

News1. The size, direction and nature of the NTN imported bearing load [The load capacity of the bearing is expressed by the basic rated load, and its value is contained in the bearing size table] The bearing load is rich in changes, such as the size of the load, whether there is only radial load, axial Whether the load is one-way or two-way, the degree of vibration or shock, etc. After considering these factors, choose the most suitable bearing type.

Generally speaking, the radial load capacity of NTN imported bearings with the same inner diameter increases in the following order: deep groove ball bearings <angular contact ball bearings <cylindrical roller bearings <tapered roller bearings <spherical roller bearings

2. Analysis of the relative tilt between the inner ring and the outer ring causes the relative tilt of the inner ring and the outer ring of the bearing (such as the deflection of the shaft caused by the load, the poor accuracy of the shaft and the housing or the installation error), and the selection can adapt to this Type of bearing under service conditions. If the relative tilt between the inner ring and the outer ring is too large, the bearing will be damaged due to internal load. Therefore, a bearing type that can withstand this tilt should be selected.

Generally speaking, the allowable tilt angle (or centering angle) increases in the following order:

Cylindrical roller bearings, tapered roller bearings, deep groove ball bearings (angular contact ball bearings), spherical roller (ball) bearings 3) NTN imported bearing type with rigidity that meets the rigidity required by the mechanical shaft system [when the bearing is under load , The contact part of the rolling element and the raceway will produce elastic deformation. "High rigidity" means that the amount of deformation of this elastic deformation is small.] In parts such as machine tool spindles and automobile final reduction gears, while increasing the rigidity of the shaft, it is necessary to increase the rigidity of the bearing.

Roller bearings are less deformed under load than ball bearings. Preloading the bearing (negative clearance) can increase rigidity. This method is suitable for angular contact ball bearings and tapered roller bearings.

3. The installation space of NTN imported bearings can be accommodated in the bearing installation space. Because the rigidity and strength of the shaft are emphasized when designing the shaft system, the shaft diameter, which is the inner diameter of the bearing, is generally determined first. However, rolling bearings have a variety of size series and types, and the most suitable bearing type should be selected from them.

The following bearings are generally used:

Deep groove ball bearings, contact ball bearings, cylindrical roller bearings

4. Rotation accuracy The bearing type with the required rotation accuracy [The dimensional accuracy and rotation accuracy of the bearing have been standardized by GB according to the bearing type] Machine tool spindles, gas turbines and control machines require high rotation accuracy, high speed and low friction, respectively. Bearings with accuracy above grade 5 should be used.

5. Assembling and disassembling the frequency and method of regular inspection of installation and disassembly. When the assembly and disassembly are frequent, it is more convenient to use cylindrical roller bearings with separable inner and outer rings, needle roller bearings and tapered roller bearings.

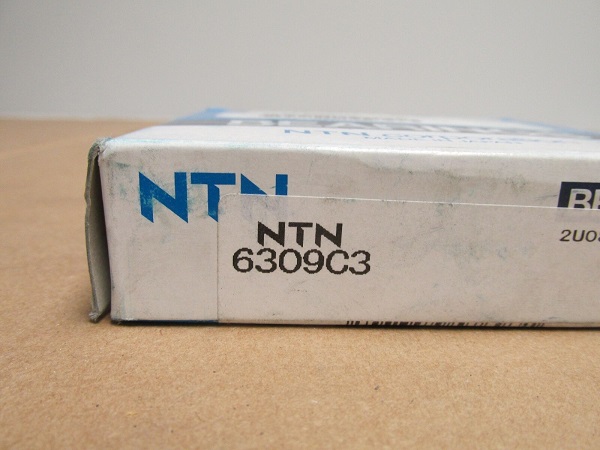

6. The NTN imported bearing type whose speed can adapt to the mechanical speed [The limit value of the bearing speed is expressed in the limit speed, and the value is shown in the bearing size table] The limit speed of the bearing is not only taken from the bearing type but also limited to the bearing size, cage type, Accuracy grade, load condition and lubrication method, etc., therefore, these factors must be considered when selecting. Click here for more information about NTN Bearing 6309C3.

The internal factors mainly refer to the three major factors that determine the quality of NTN bearings, such as structural design, manufacturing process and material quality.

First of all, if the structural design is reasonable and advanced, the bearing life will be longer. The manufacture of NTN bearings generally involves multiple processing procedures such as forging, heat treatment, turning, grinding and assembly. The rationality, advancement and stability of each processing technology will also affect the life of the bearing. Among them, the heat treatment and grinding processes that affect the quality of the finished bearing are often more directly related to the failure of the bearing. In recent years, studies on the deteriorating layer of the bearing working surface show that the grinding process is closely related to the bearing surface quality.

The metallurgical quality of NTN bearing materials used to be the main factor affecting the early failure of rolling bearings. With the progress of metallurgical technology (such as vacuum degassing of bearing steel, etc.), the quality of raw materials has been improved. The proportion of raw material quality factors in bearing failure analysis has dropped significantly, but it is still one of the main factors affecting bearing failure. The proper selection of materials is still a factor that must be considered in bearing failure analysis.

The main task of NTN bearing failure analysis is to find out the main factors causing bearing failure based on a large number of background materials, analysis data and failure modes, so that targeted improvement measures can be proposed to extend the service life of the bearing and avoid sudden occurrence of the bearing Early failure of sex.