News

News1. The impact of vibration on KOYO imported bearings.

In normal use, vibration is very sensitive to bearing damage, peeling, indentation, rust, cracks, wear, etc. will be reflected in the bearing vibration measurement. Therefore, by using a special bearing vibration measuring device (frequency analyzer, etc.), the magnitude of the vibration can be measured, and the specific abnormality cannot be inferred through the frequency division. The measured value varies depending on the use condition of the bearing or the installation position of the sensor, so it is necessary to analyze and compare the measured value of each machine in advance to determine the judgment standard.

2. The influence of temperature on the bearing.

High temperature often indicates that KOYO imported bearings are in abnormal conditions. High temperature is also harmful to the lubricant of the bearing. Sometimes bearing overheating can be attributed to the lubricant of the bearing. Long-term continuous rotation of bearings at temperatures exceeding 125°C will reduce bearing life. Causes of high temperature bearings include: insufficient or excessive lubrication, lubricants. Containing impurities, excessive load, bearing ring damage, insufficient clearance, and high friction caused by oil seals, etc.

In the process of using KOYO imported bearings, the temperature rise is easy to occur. When the bearing temperature rises, first judge whether it is misoperation. If it does rise, the following treatments should be done:

1. Check whether the cooling water pressure, water flow and piping system are normal. If the water pressure is low, it may be that the filter is clogged, and when it cannot be processed in time, it can be shut down for processing. When it is confirmed that it can work, it can be put into use.

2. Check the oil pressure of the governor. If the oil pressure is low, the cooling water hydraulic valve may close.

3. Check whether the imported KOYO bearing has abnormal noise, and check whether the bearing swing is abnormal.

4. Take an oil sample to observe whether the oil color has changed, and conduct a laboratory test to see whether it has deteriorated. If the deterioration is confirmed, stop the machine and replace with new oil.

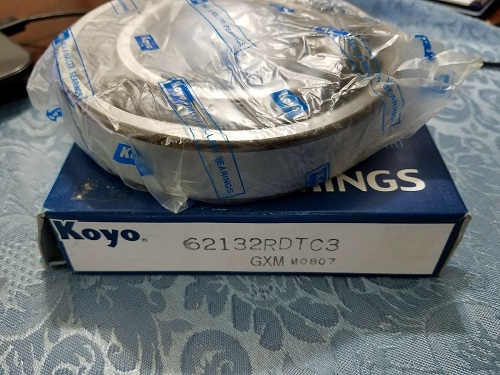

5. Check whether the oil level of the oil level is normal. If it is abnormal, check whether the oil tank drain valve is tightly closed. If it is closed tightly, oil should be refilled; if the sealing rubber gasket is leaking oil, shut down the machine for processing. Eric Bearing Limited provides KOYO Bearing 6213-2RD, contact us for more details.

Vibration can be said to be quite sensitive to the damage of KOYO imported bearings, peeling, indentation, rust, cracks, wear, etc. will be reflected in the bearing vibration measurement. Therefore, by using a special bearing vibration measuring device (frequency analyzer, etc.), the magnitude of the vibration can be measured, and the specific abnormality cannot be inferred through the frequency division. The measured value varies depending on the use condition of the bearing or the installation position of the sensor, so it is necessary to analyze and compare the measured value of each machine in advance to determine the judgment standard.

Let's take a look at the impact of temperature on the bearing. High temperature often indicates that KOYO imported bearings are in abnormal conditions. High temperature is also harmful to the lubricant of the bearing. Sometimes bearing overheating can be attributed to the lubricant of the bearing. Long-term continuous rotation at temperatures exceeding 125°C will reduce bearing life. Causes of high temperature bearings include: insufficient or excessive lubrication, lubricants. Containing impurities, excessive load, bearing ring damage, insufficient clearance, and high friction caused by oil seals, etc.

Therefore, it is necessary to continuously monitor the temperature of imported KOYO bearings, whether it is to measure the bearing itself or other important parts. If the operating conditions remain unchanged, any temperature change can indicate that a malfunction has occurred.

KOYO imported bearing temperature can be measured regularly with the help of a thermometer, such as a digital thermometer, which can accurately measure the bearing temperature and display it in units of ℃ or Fahrenheit. The important bearing means that when it is damaged, it will cause the equipment to stop. Therefore, it is best to install a temperature detector for this type of bearing.

Rolling bearing is a kind of precision basic products, proper storage and reasonable installation will bring satisfactory results to your use. The bearing will affect and destroy the original quality of KOYO bearing due to pollution, corrosion, deformation and other factors, and it will not achieve your expected use effect.

1. Storage: KOYO bearings should not be exposed to the air. The storage warehouse should be kept clean and dry. The relative humidity of the inventory air should not exceed 55%. The temperature should be appropriate. After folding and sealing, the bearings that are not used temporarily should be oiled and sealed. Also avoid putting it together with corrosive substances such as acids, alkalis and chemicals.

2. Transportation: The bearing should avoid deformation and damage due to bumps and drops during transportation.

3. Cleaning: Except for the sealed bearings with cover on both sides, the other bearings are added with anti-rust oil before leaving the factory. They should be cleaned before use. Usually the bearings are immersed in gasoline mixed with 8-10% mineral oil. Hold the inner ring with one hand and rotate the outer ring with the other hand to wash away the anti-rust agent on the bearing surface. After cleaning, the bearing cannot be rotated anymore. After the gasoline is volatilized, lubricating oil or grease is injected. Do not stick to dust, moisture, hand sweat, so as not to affect the rotation accuracy and rust.

4. Loading and unloading: The installed shaft or hole should be smooth and free of burrs. Carefully measure whether the diameter of the shaft or hole meets the standard. Recognize the KOYO bearing reference surface. For the bearing installed on the shaft, only force can be applied to the inner ring. For the bearing installed in the hole, the force is on the outer ring, and the force should be evenly distributed on the circumference of the end face of the ring. Do not hit with force on one side to avoid the phenomenon of skewed biting. When loading and unloading bearings with large interference, use counter bearings. The preheating method is carried out, and the heating temperature is between 90-100℃. For double-row spherical roller bearings and single-row tapered bearings, pay more attention, because the inner rib is very thin, and the hole is easily broken if accidentally.

5. Inspection: After the installation of the KOYO bearing, it should rotate flexibly and without stopping. In addition, the dimensional accuracy and rotation accuracy of the bearing have been checked before leaving the factory to ensure the quality. The traces on the inner and outer rings of the bearing and the black on the chamfers of the bearing rings are all caused by the quality assurance process and inspection methods. It is purely normal and does not affect product quality.