News

NewsThe riveting or welding quality of the cage is mainly to observe whether the rivet head is offset, skewed, loose, lacking meat or "double eyelids", whether the welding position is correct, whether the welding point is too large or too small, whether the welding is weak or excessive Causing the jamming of rolling elements, whether the quality of the pressure slope, edge closing, caulking and gouging of certain cages is guaranteed, whether the rolling elements can not fall out of the cage and can rotate freely. As a result, the noise and rotation accuracy of the TIMKEN bearing are reduced. If the cage falls apart, the bearing may cause mechanical failure or accidents.

Skinning and folding, the parts of these two defects are not firmly bonded to the base metal, and there are often decarburization or carbon-poor phenomena around them to varying degrees. The materials are easy to collapse, dent or wear, which is very detrimental to the life and accuracy of TIMKEN bearings. .

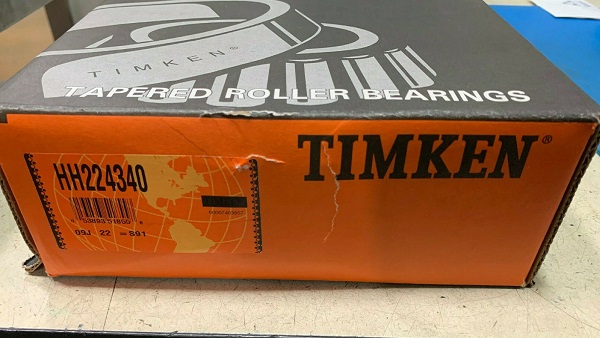

Various cracks, such as raw material cracks, forging cracks, heat treatment cracks and grinding cracks, will become the source of stress concentration and rapidly expand during the operation of the TIMKEN bearing in the future, causing the TIMKEN bearing to rupture, which will affect the life and work of the TIMKEN bearing. Security has a great impact. In fact, for important-purpose TIMKEN bearings, TIMKEN bearing factory has carried out 100% magnetic or radiographic inspection of its component parts. Rust, black skin and pitting, the latter two are defects that easily store moisture and dirt, and are most likely to develop into rust. Rust is a source of pollution that causes poor installation, early wear and fatigue. Severe corrosion will cause TIMKEN bearings to be scrapped. TIMKEN Bearing HH224340 online, contact us to buy it.

First, what are the requirements for the installation surface and installation site?

Impurities cannot enter the TIMKEN bearing. If iron filings, dust and other impurities enter the TIMKEN bearing, it will cause noise and vibration when the TIMKEN bearing rotates, and even cause damage to the raceway and rolling elements, resulting in damage to the TIMKEN bearing. Therefore, before installing TIMKEN bearings, ensure that the installation surface and installation environment are clean and clean.

Second, do TIMKEN bearings need to be cleaned before installation?

The surface of TIMKEN bearing is coated with anti-rust oil. Before installation, it should be carefully cleaned with clean gasoline or kerosene, and then coated with clean and high-quality lubricating grease before installation and use. Cleanliness has a great influence on the service life and noise of TIMKEN bearings. But it must be specially reminded that: fully enclosed TIMKEN bearings (TIMKEN bearings with dust caps or seals) do not need to be cleaned and refueled.

Third, how to choose lubricating grease?

The quality of lubrication seriously affects the rotation and life of TIMKEN bearings. The general principle of choosing grease is: grease is composed of base oil, thickener and additives. The performance of different types or different brands of greases of the same type or the same type is very different. Large, the allowable limit speed is different, pay attention to when choosing. The performance of grease is mainly determined by the base oil. Generally, low-viscosity base oils are suitable for low-temperature and high-speed environments, and high-viscosity base oils are suitable for high-temperature, high-load operating environments. The thickener is also related to the lubricating performance, and the water resistance of the thickener determines the water resistance of the grease. In principle, greases of different brands cannot be mixed together. Moreover, even greases with the same thickener will have a bad influence on TIMKEN bearings due to different additives.

Fourth, when lubricating TIMKEN bearings, is the more grease the better?

When lubricating TIMKEN bearings, the more grease, the better. Excessive grease in the TIMKEN bearing will cause excessive stirring of the grease, which will result in excessive temperature. The amount of grease filled in TIMKEN bearings should be 30%-50% of the internal space of TIMKEN bearings.

Fifth, is the radial clearance of the TIMKEN bearing as small as possible?

Not all operating environments require TIMKEN bearings to have a minimum working clearance. You must select the appropriate clearance according to the conditions of use. In the national standard 4604-93, the radial clearance of rolling TIMKEN bearings is divided into five groups: 2 groups, 0 groups, 3 groups, 4 groups and 5 groups. The clearance values are arranged from small to large, of which group 0 is the standard ordinary clearance . The standard radial clearance group is suitable for general operating conditions, normal temperature and common interference fit; TIMKEN bearings working under special conditions such as high temperature, high speed, low noise, low friction, etc. should use large radial clearance; TIMKEN bearings used in precision spindles and machine tool spindles should be selected with a smaller radial clearance.We provide TIMKEN Bearing H424249/H414210, contact us for more information.

Eric Bearing Limited has over 10 years' experience of exporting bearings. Our customers are in more than 100 countries and regions around the world. Our products have been highly recognized and evaluated by customers.In the future, we will continue to expand our business scope. Bring better products to customers.