IKO bearing use factors mainly refer to whether the installation adjustment, use and maintenance, maintenance and repair meet the technical requirements. According to the technical requirements of bearing installation, use, maintenance, and maintenance, monitor and inspect the load, speed, working temperature, vibration, noise and lubrication conditions of the bearing in operation. If abnormalities are found, immediately find the cause, make adjustments, and make Back to normal. The installation condition is one of the most important factors in the use factor. The bearing is often caused by improper installation and the stress state between the parts of the entire set of IKO bearings changes. The bearing runs in an abnormal state and ends its service life early. The main internal factors are It refers to the three major factors that determine the quality of IKO bearings, such as structural design, manufacturing process and material quality.

The metallurgical quality of IKO bearing materials used to be the main factor affecting the early failure of rolling bearings. With the progress of metallurgical technology (such as vacuum degassing of bearing steel, etc.), the quality of raw materials has been improved. The proportion of raw material quality factors in bearing failure analysis has dropped significantly, but it is still one of the main factors affecting bearing failure. The proper selection of materials is still a factor that must be considered in the failure analysis of IKO bearings.

The manufacture of IKO bearings generally involves multiple processing procedures such as forging, heat treatment, turning, grinding and assembly. The rationality, advancement and stability of each processing technology will also affect the life of the bearing. Among them, the heat treatment and grinding processes that affect the quality of the finished IKO bearing are often more directly related to the failure of the bearing. In recent years, the research on the deteriorating layer of IKO bearing working surface shows that the grinding process is closely related to the surface quality of IKO bearing.

The main task of IKO bearing service life analysis is to find out the main factors causing bearing failure based on a large number of background materials, analysis data and failure modes, so as to propose improvement measures to extend the service life of IKO bearings and avoid bearing occurrence Sudden early failure.

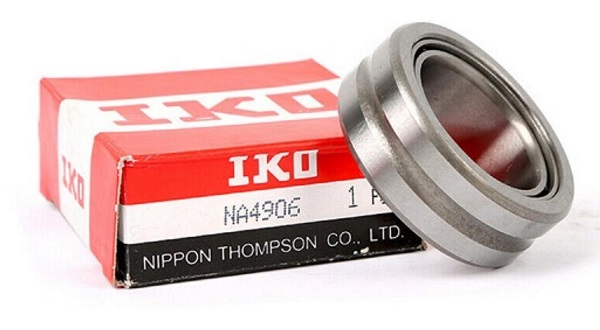

Click here for more details about IKO NA4906.

Strong metallic tone

1. Abnormal load: select the appropriate assembly clearance and pre-tightening force

2. Poor assembly: improve the machining accuracy of the shaft and improve the installation method

3. Insufficient lubricant: supplement or use suitable lubricant

Regular tone

1. Foreign matter causes channel corrosion, indentation, and scars: clean related parts and use clean grease

2, channel spalling: fatigue wear, replace IKO bearing

Irregular sound

1. Foreign matter intrusion: clean related parts and use clean grease

2, the clearance is too large: pay attention to the fit and choose the appropriate clearance

3. Steel ball scars: the steel ball is peeled off due to fatigue or foreign matter is stuck, replace the IKO bearing

Abnormal temperature rise

1. Too much lubricant: reduce lubricant

2. Insufficient or unsuitable lubricant: add lubricant or choose suitable lubricant

3, the mating surface creep or the sealing device is too large: IKO bearing outer diameter or inner diameter mating surface is corrected, the sealing form is changed

The rotation vibration of the shaft is large

1. Spalling: Fatigue spalling, replace the IKO bearing

2. Poor assembly: improve the machining accuracy of the shaft and improve the installation method

3. Foreign matter intrusion: clean related parts and use clean grease

Lubricant leakage and discoloration

1. Too much lubricant: reduce lubricant

2. Foreign matter invasion: cleaning related parts

News

News