News

NewsGenerally, the space in which IKO bearings can be installed is limited. In most cases, the shaft diameter (or bearing inner diameter) is based on mechanical design or other design constraints. Therefore, the choice of IKO bearing type and size is based on the inner diameter of the IKO bearing. Therefore, the main dimension tables of standard IKO bearings are compiled according to the international standard inner diameter dimensions.

There are many sizes of standard bearings. It is best to use standard IKO bearings in the design of mechanical devices. (This design to whether the bearings are easy to purchase, I will say a digression here. Some IKO bearing catalogs do have models, but some are non-standard. IKO bearings are not available in stock in mainland China, and sometimes the futures will be very long. Therefore, the time cost and the cost of later replacement should be considered when selecting the bearing.) The load of the IKO bearing, the load imposed on the bearing, its nature, size, The direction is changeable. Generally, the rated basic load is shown on the dimension table. But axial load and radial load, etc. are also important factors in choosing a suitable IKO bearing. When the size of the ball and needle roller bearings are the same, the needle roller bearings usually have a higher load capacity and can withstand greater vibration and shock loads.

After the IKO bearing is installed, in order to check whether the installation is correct, it is necessary to carry out a running inspection. Small machines can be rotated by hand to confirm whether they rotate smoothly. The inspection items include poor operation due to foreign objects, scars, and indentations, unstable torque due to poor installation and poor processing of the mounting seat, excessive torque due to too small clearance, installation error, and seal friction, etc. Wait. If there is no abnormality, power operation can be started.

Large-scale machinery cannot be rotated manually, so immediately cut off the power after starting without load, and the machinery is idling. Check for vibration, noise, and contact with rotating parts. After confirming that there is no abnormality, enter the power operation.

The power operation starts at a low speed with no load and slowly increases to the rated operation under the specified conditions. The items to be checked during the test run are whether there are abnormal sounds, changes in IKO bearing temperature, leakage or discoloration of lubricants, etc. If an abnormality is found, the operation should be stopped immediately, the machine should be inspected, and the bearing should be removed for inspection if necessary.

IKO bearing temperature can generally be estimated based on the external temperature of the bearing seat. However, it is more accurate to use the oil hole to directly measure the temperature of the outer ring of the bearing. The temperature of the bearing gradually increases from the start of operation, and usually stabilizes after 1 to 2 hours. If the bearing is installed improperly, the temperature will rise sharply, resulting in abnormally high temperature. The reasons include too much lubricant, too small bearing clearance, poor installation, and excessive friction of the sealing device. In the case of high-speed rotation, the wrong choice of IKO bearing structure and lubrication method is also the reason.

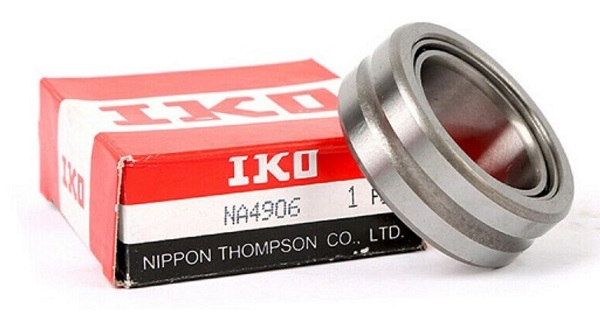

The rotating sound of IKO bearings is checked with a stethoscope, etc., there are strong metal noises, abnormal sounds, irregular sounds, etc., indicating abnormalities. The reasons include poor lubrication, poor shaft or bearing seat accuracy, bearing damage, and foreign matter intrusion. Click here for more detail about IKO Bearing NA4906.

[1] Size limitation. Generally, the space in which IKO bearings can be installed is limited. In most cases, the shaft diameter (or bearing inner diameter) is based on mechanical design or other design constraints. Therefore, the choice of bearing type and size is determined by the inner diameter of the bearing. Therefore, the main size tables of standard bearings are compiled according to the international standard inner diameter size.

[2] The speed, the permitted speed is determined according to the IKO bearing type, size, accuracy, cage type, load, lubrication method, and cooling method. The bearing table lists the permitted speeds of standard precision bearings under oil lubrication and grease lubrication. Generally, deep groove ball bearings, self-aligning ball bearings and cylindrical roller bearings are suitable for high-speed operation.

[3] IKO bearing tolerance, bearing dimensional accuracy and rotation accuracy are based on ISO and JIS standards. For machinery that requires high precision and high-speed operation, it is recommended to use bearings with accuracy of 5 or above. Deep groove ball bearings, radial thrust ball bearings or cylindrical roller bearings are suitable for machinery with high operating accuracy. Rigidity. When the contact surface of the movable elastic body and raceway of the bearing is compressed, it will produce elastic deformation. Some machines need to minimize elastic deformation. Roller bearings produce smaller elastic deformations than ball bearings

[4] In some cases, IKO bearings need to be preloaded to increase rigidity. This procedure is usually used for deep groove ball bearings, radial thrust ball bearings and tapered roller bearings to offset the inner and outer rings, shaft bending, shaft or bearing housing tolerance changes, and matching errors will lead to eccentricity of the inner and outer rings. In order to prevent the eccentric angle from being too large, self-aligning ball bearings, self-aligning roller bearings, or self-aligning bearing seats are better choices. The voice frequency and torque, and the movable bearing are manufactured according to high-precision standards, so the voice and torque are small. Deep groove ball bearings and cylindrical roller bearings are used together for occasions that have special requirements for low noise and low torque.

[5] Installation and disassembly, some applications need to be disassembled and installed frequently to ensure that the inspection and maintenance can be carried out according to the location. Bearings in which the inner and outer rings can be installed separately, such as cylindrical bearings, needle roller bearings, and tapered bearings are very suitable for this occasion. The tapered hole type self-aligning ball bearing and self-aligning roller bearing also simplify the installation procedure with the help of the sleeve.

The bearings sold by Eric Bearings Limited are of excellent quality, and the price is much cheaper than other distributors. The products are exported to more than 50 countries and regions in the world, winning wide acclaim from customers and establishing long-term cooperative relations with them. In order to expand the scope of business, we also hope to establish trade relations with more customers and develop together.