News

NewsWhether imported or domestic bearings will fail one day, the general failure is that the life of the bearing has expired. If it is less than the life of the faulty TIMKEN bearing. Then there is a bearing problem, which leads to premature failure of less than the service life of the bearing, and the current bearing quality is good, and generally does not fail prematurely, so if you want to buy a bearing, the bearing can be regarded as a matter of course. There are many types of bearings. But I still recommend the use of Swedish bearings, because the best quality bearings will generally not fail prematurely, but sometimes there will be some shelling bearing failures. We introduced the shelling knowledge of bearing failures.

The discrimination of fatigue shelling and peeling is: when shelling TIMKEN bearing alloy and steel, it can be clearly seen that the interface is separated, and some interface residues of bearing alloy and fatigue can be found in the strip steel.

This is due to the poor bonding effect between TIMKEN bearing alloy and steel back metal. The combination of the surface layer of the steel metal alloy and the unfavorable factors: the surface of the base metal oxide film, dust, coal or petroleum; the oxide of molten alloy iron or entering the bearing surface; the gas escaping from the metal is cooled and solidified; the pouring temperature is improper; the alloy composition No, it is not equal to steel components.

The general TIMKEN bearing failure mechanism and failure mode show that, despite the precise and reliable institutional basis of rolling bearings, improper use can cause early failure. Under normal circumstances, if the bearing is used correctly, the latest fatigue life can be used. Exceeding the manufacturing, installation quality and use conditions of the host and precision parts, lubrication, external enemy invasion, thermal influence and other factors, the early failure of the host bearing sudden failure. Therefore, the correct and reasonable utilization of the bearing is a systematic project. The structural design of the bearing, the link that causes the early failure in the manufacturing and installation process, and the corresponding measures can be taken to effectively improve the service life of the bearing and the host.

A part of the dynamic surface material of TIMKEN bearing falls off like fish scales. This phenomenon is called fatigue spalling. During the operation of the dynamic elastic bearing, it bears a certain load, even if it is a static load, but the stress on the steel ball and raceway It is reciprocating in cycles, and the material will be fatigued by moving and springing so that the bearing reaches the end of its life. In addition, there are several different definitions of bearing "life", one of which is the so-called "working life", which means that the actual life of a bearing before it is damaged is caused by wear and tear, and damage is usually not caused by fatigue, but Caused by wear, erosion, seal damage, etc.

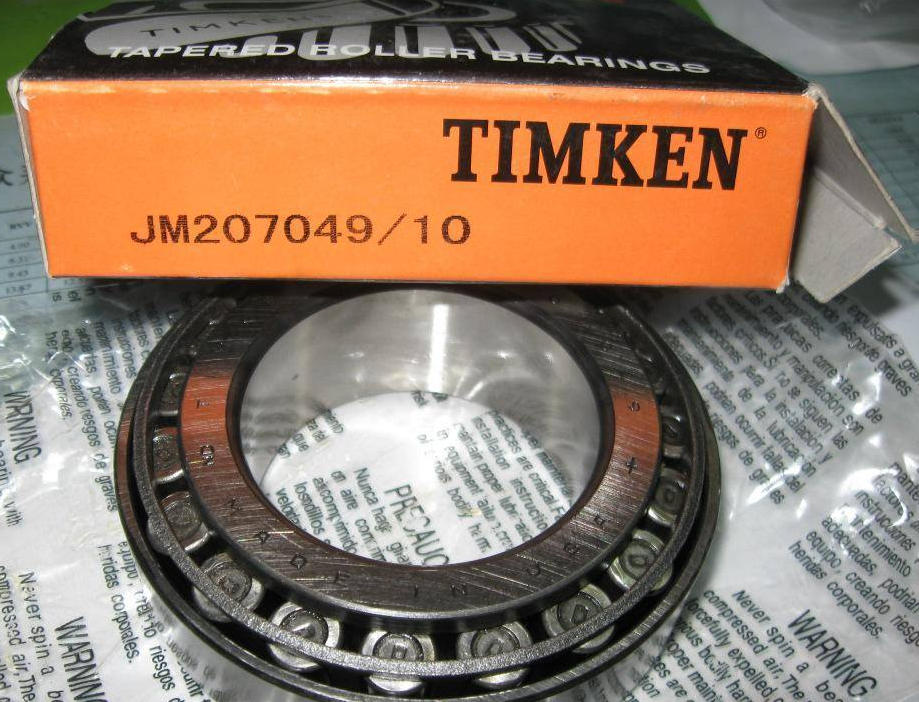

Welcome to visit our website for more information about TIMKEN JM207049/10.

However, no matter in the laboratory test or in actual use, it can be clearly seen that the bearing has the same appearance under the same working conditions, but the actual life is very different.

The life revolution of TIMKEN bearing (or the number of hours of work at a certain speed) is defined: the bearing within this life should be initially fatigued and damaged (flaking or defect) on any of its bearing rings or moving projectiles. Most of the bearings are broken due to many reasons-beyond the original estimated load, ineffective sealing, too small bearing clearance caused by tight fit, etc.

Any of these factors has its own special type of damage and will leave special damage marks. Therefore, inspecting damaged TIMKEN bearings, in most cases, you can find its possible causes. Generally speaking, one-third of bearing damages are caused by fatigue damage, and the other third are caused by poor lubrication. One third of this is due to contamination entering the bearing or improper installation and treatment.

However, these types of damage are also related to industries. For example, in the pulp and paper industry, bearing damage is mostly caused by poor lubrication or contamination rather than material fatigue.

The bearings sold by Eric Bearings Limited are of excellent quality, and the price is much cheaper than other distributors. The products are exported to more than 100 countries and regions in the world, winning wide acclaim from customers and establishing long-term cooperative relations with them. In order to expand the scope of business, we also hope to establish trade relations with more customers and develop together.