The assembly of rolling bearings should be determined according to the structure, size and mating nature of bearing components.

General assembly methods of rolling bearings include hammer method, compression method, hot loading method and cold shrinking method, etc.

1, the preparation work before the assembly of rolling bearings

(1) According to the bearing to be assembled, prepare the required tools and measuring tools.

According to the drawing requirements, check whether the matching parts with bearings are defective, rust and burr, etc.

(2) Clean the parts compatible with the bearing with gasoline or kerosene, wipe it with a clean cloth or dry it with compressed air, and then coat it with a thin layer of oil.

(3) Check whether the bearing model is consistent with the drawing.

(4) The bearings sealed with anti-rust oil can be cleaned by gasoline or kerosene;

Use thick oil and anti-rust oil sealing available light mineral oil heating, dissolution and cleaning, cooling and then use gasoline or kerosene cleaning, wipe clean for use;

There is no need to clean bearings with dust caps and sealing rings on both sides or coated with antirust and lubricating grease.

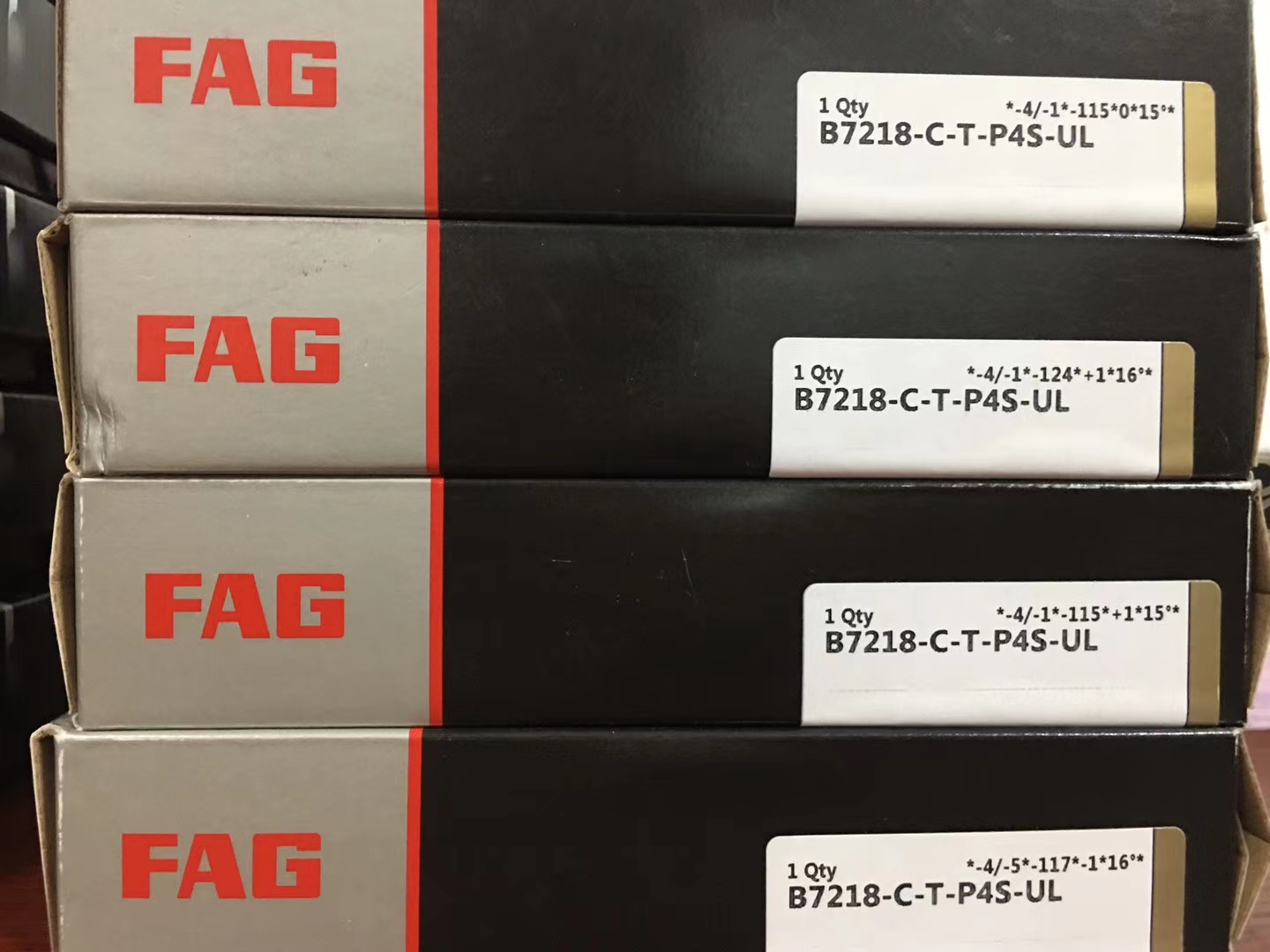

Click here for more details about FAG B7218-C-T-P4S-UL.

2. Assembly method of rolling bearings

(1) Assembly of cylindrical bore bearings

First, the assembly sequence of non-separable bearings (such as deep groove ball bearings, self-aligning ball bearings, self-aligning roller bearings, angular contact bearings, etc.) should be determined by the tightness of the seat ring fit.

When the inner ring is tighter with the journal, and the outer ring is looser with the shell, the bearing is installed on the shaft first, and then the coaxial is loaded into the shell together.

When the bearing outer ring is tightly fitted with the shell hole, and the inner ring is loosely fitted with the shaft journal, the bearing should be pressed into the shell first;

When the inner ring and the shaft, the outer ring and the shell hole are tightly matched, the bearing should be pressed on the shaft and the shell hole at the same time.

Second, because of the separation of bearings (such as tapered roller bearings, cylindrical roller bearings, needle roller bearings, etc.) the inner and outer rings can be free from the assembly, the inner ring and the rolling body are installed on the shaft together, the outer ring is installed in the shell, and then adjust the clearance between them.

The common assembly methods of bearings are hammering method and compression method.

Figure 1-A is a special sleeve pressure, Figure 1-B is a symmetrical copper bar in the bearing inner ring (or outer ring) face uniform knock.

FIG. 2 is the method of pressing the inner and outer ring of the bearing into the hole of the journal and the bearing seat respectively by the presser method.

If the journal size is large and the interference is large, the hot loading method can be used for convenient assembly. That is, the bearing is heated in oil with a temperature of 80~ 100~C, and then matched with the shaft at room temperature.

When the bearing is heated, it should be put on the mesh in the oil groove (Figure 3) to avoid the bearing contacting the bottom of the box which is much higher than the oil temperature, and to prevent the contact with the precipitate dirt at the bottom of the box.

For small bearings, they can be hung on hooks and immersed in oil to heat.

Bearings filled with grease inside with dustproof cover or sealing ring should not be assembled by hot loading method.

(2) When the assembly interference of the conical bore bearing is small, it can be directly mounted on the journal with a taper, and can also be installed on the taper surface of the fixing sleeve or the unloading sleeve;

For the large size of the journal or with large interference and often disassembled conical bore bearings, commonly used hydraulic sleeve legal disassembly.

(3) Assembly of thrust ball bearings Thrust ball bearings are divided into loose ring and tight ring. During assembly, the tight ring should be on the end face of the rotating part, and the loose ring on the end face of the stationary part. Otherwise, the rolling body will lose its function, and the wear between the matching parts will be accelerated.

News

News