News

NewsIn previous Bearing Trivia entries, we introduced the fact that bearings are used in many machines and are a very important machine component. We focused in those columns on topics like bearing structure and so on.

When designing a machine, it is important to select the bearing that is right for that machine.

Eric Bearing Limited has published a guide for selecting the right bearing in its Ball & Roller Bearings Catalog, but the catalog uses a large number of technical terms and is very long, so many people seem to have trouble handling it.

That's where this column comes in. We will explain the key points for selecting the type of bearing that is right for your machine.

The catalog uses the terms "bearing" and "rolling bearing" interchangeably. This column does not use the term "rolling bearing" as a general rule.

1. What are the criteria for selecting bearings?

Bearings come in a variety of types, and their sizes can range from just a few millimeters to over ten meters in diameter.

When selecting from among these many varied types of bearings, the bearing that is right for your machine, the following two criteria are very important.

Criterion 1: It should be appropriate for the machine's usage environment and the operating condition that is being demanded of the bearing

Criterion 2: It should be easy to acquire replacement bearings and it should facilitate maintenance/inspection of the machine

If these criteria are met, damage of the machine can be reduced, the time needed to replace the bearings when performing repairs can be shortened, and the machine can be used for a longer period of time.

In this way, selecting the appropriate bearing will lead to machine design that is economically superior!

2. The order of priority for selecting bearings

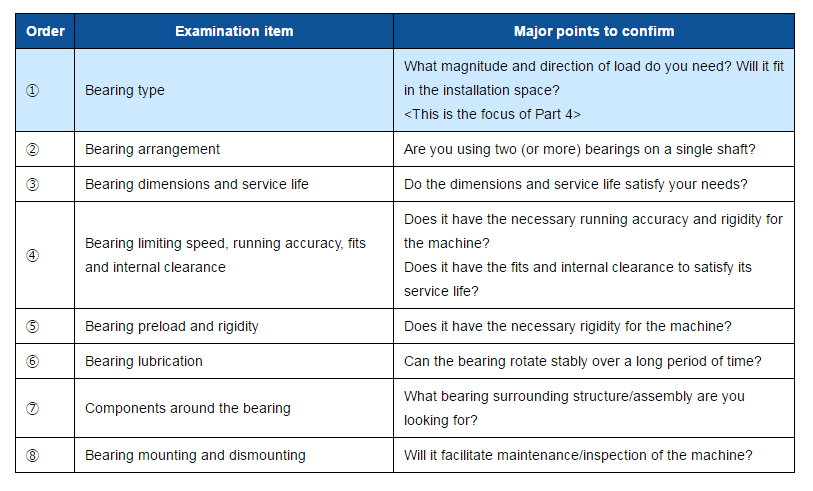

In the "How to Select the Right Bearing" columns, we will select the optimal bearing based on the ordering shown in Table 1, below.

Please note that the following order is only a guideline.

When you actually select the bearing to use, the most important factors are past success history and points of improvement, so it is not necessary to follow this order to the letter.

3. How to select the type of bearing

When designing a machine, most people first decide on the dimensions of the shaft to satisfy the strength requirement, and then select the bearing based on that.

1) If the load will be mostly radial (perpendicular to the shaft), use a radial bearing, and if the load will be mostly axial* (same direction as the shaft), use a thrust bearing. * Axial loads are sometimes called thrust loads.

2) If the load on the bearing will be light, use a ball bearing, and if it will be heavy, use a roller bearing.

3) If a radial load and an axial load are both placed on a single bearing at the same time (combined load), a light combined load calls for a deep groove ball bearing or an angular contact ball bearing, while a heavy combined load calls for a tapered roller bearing.

If there is a heavy axial load being applied from both directions, you can combine two or more bearings, or use a double-row bearing.

Click here for more details about SKF Bearing W 626-2Z.

4. Bearing installation space

Our bearing catalog contains a table showing the boundary dimensions (dimensions required for bearing installation with shaft and housing) as in Table 3, below. Using the table of boundary dimensions, select a bearing type that will fit in the installation space based on the dimensions of the shaft or housing.

1) In the table of boundary dimensions, the dimensions such as bearing outside diameter and width (or height in the case of a thrust bearing), corresponding to a specific bearing bore diameter, are shown in series.

2) The "dimension series code" refers to a combination of the width series and the diameter series that has a stepped bearing outside diameter with respect to the bearing bore diameter.

3) Even if a bearing has the same bore diameter, there are several types of width and outside diameter, so select the appropriate bearing from among them.

Some people choose bearings based on the outside diameter of the bearing that matches the dimensions of the housing.

For more information about SKF Bearing W 623-2Z, click here.

5. Conclusion

When selecting the bearing that is right for your machine, it is important that the bearing be appropriate for the requirements of the usage environment and that it be easily acquired for replacement. In the "How to Select the Right Bearing" columns, we will show you how to do this.

In this month's column, "How to select the type of bearing," we conveyed the following points:

1) Select the right bearing type based on the magnitude and direction of the load.

2) Select a bearing that matches the dimensions of the shaft or housing from the bearing boundary dimensions table.

3) Check that the type of bearing you have selected is appropriate by using the "Performance comparison of bearing type" with the bearing usage criteria.

Eric Bearing Limited has more than ten years of foreign trade export experience, and its products have been exported to more than 50 countries and regions, which has won wide acclaim and recognition from customers. Looking forward to further cooperation with you in the future.