News

NewsThe inspection of the TIMKEN bearing should be carried out under the astigmatism lamp, and the appearance and cracks of the TIMKEN bearing should be carefully observed.

1. Peeling and folding:

The locality of these two defects is not tightly bonded to the base metal, and there are often decarburization or carbon depletion around them. The material is easy to collapse, dent, or wear, which is very detrimental to TIMKEN bearing life and accuracy.

2. Riveting or welding quality of the cage:

Mainly observe whether the rivet head is misaligned, skewed, slack, lack of meat or double eyelids, whether the welding position is correct, whether the welding point is too large or too small, whether the welding is not strong or excessive welding causes the phenomenon of stuck rolling bodies. The above items are the key parts of our inspection of SKFTIMKEN bearings.

3. Rust, black skin and pitting:

The latter two are defects that are easy to store moisture and dirt, and are most likely to develop into rust. Corrosion is a source of pollution that leads to poor installation, early wear and fatigue. Severe corrosion will make TIMKEN bearings obsolete.

4. Various mechanical scars:

Such as abrasions, scratches, pressure injuries, bumps, etc., will cause poor installation of TIMKEN bearings, causing eccentric load and stress concentration, resulting in a reduction in rotation accuracy and service life.

5. Various cracks:

Such as raw material cracks, forging cracks, heat treatment cracks and grinding cracks, etc., these cracks will become a source of stress concentration and expand rapidly during the operation of TIMKEN bearings in the future, causing TIMKEN bearings to rupture, which will greatly affect the life and working safety of TIMKEN bearings. Big. In fact, for the important use of TIMKEN bearings, TIMKEN bearing factory has carried out 100% magnetic or radiographic inspection of its component parts.

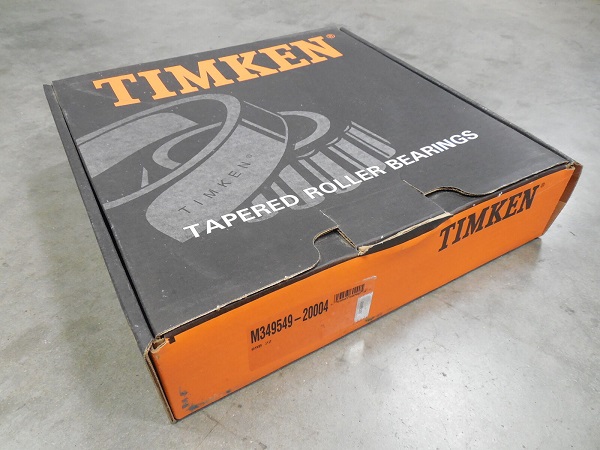

Contact us for more details about TIMKEN Bearing M349549-20004.

Disassembly methods of various types of TIMKEN bearings

The disassembly of the TIMKEN bearing should be carried out carefully as in the installation. Be careful not to damage the TIMKEN bearing and its parts, especially the interference fit of the TIMKEN bearing disassembly, the operation is difficult. Therefore, in the design stage, it is necessary to consider the ease of disassembly in advance, and it is also very important to design and make disassembly tools as needed. When disassembling, research the disassembling method and sequence according to the drawings, and investigate the matching conditions of TIMKEN bearings in order to obtain foolproof operation of disassembly.

1. Disassembly of the outer ring

To disassemble the interference fit outer ring, set several screws for the outer ring to squeeze the screw in advance on the circumference of the housing, and tighten the screw equally on one side while removing. These screw holes are usually covered with blind plugs, tapered roller TIMKEN bearings, and other separate TIMKEN bearings. Several cuts are provided on the housing shoulders, using pads, using a press to remove, or gently tapping to remove.

2. Disassembly of cylindrical bore bearings

The disassembly of the inner ring can be pulled out using a pressure machine. At this time, pay attention to let the inner ring bear its pulling force.

The hydraulic method is used to disassemble the inner ring of the large TIMKEN bearing. Apply oil pressure through the oil hole provided on the shaft to make it easy to pull. The wide-width TIMKEN bearing is used in combination with the drawing method for the disassembly operation.

The induction heating method can be used to dismantle the inner ring of NU and NJ cylindrical roller bearings. The method of heating the local area in a short time to make the inner ring expand and pull.

3. Disassembly of tapered hole TIMKEN bearing

Remove the relatively small TIMKEN bearing with adapter sleeve, support the inner ring with a stopper fastened on the shaft, turn the nut back several times, and use the block to hit and remove with a hammer.

Large-scale TIMKEN bearings are easier to disassemble by hydraulic pressure. The oil is pressurized in the oil hole on the tapered hole shaft to expand the inner ring and disassemble the TIMKEN bearing. During operation, the TIMKEN bearing may suddenly come out. It is better to use the nut as a stopper.