News

News

Bearings play a crucial role in the packaging industry, ensuring smooth and efficient operation of various machinery. Their primary function is to reduce friction between moving parts, enhance precision, and prolong equipment lifespan.

Key Applications of Bearings in Packaging

Conveyor Systems

Bearings are widely used in conveyor belts to facilitate the smooth transportation of packaged goods. They help maintain consistent speed and reduce energy consumption.

Filling and Sealing Machines

High-precision bearings ensure accurate filling and sealing by minimizing vibration and misalignment, which is essential for maintaining product quality.

Labeling and Coding Equipment

Bearings enable precise movement in labeling machines, ensuring correct placement of labels and barcodes on packages.

Robotic Packaging Systems

Modern automated packaging lines rely on bearings for robotic arms and grippers, allowing high-speed and repeatable operations.

Wrapping and Palletizing Machines

Bearings support rotational and linear movements in wrapping and palletizing systems, improving efficiency in bulk packaging.

Types of Bearings Used

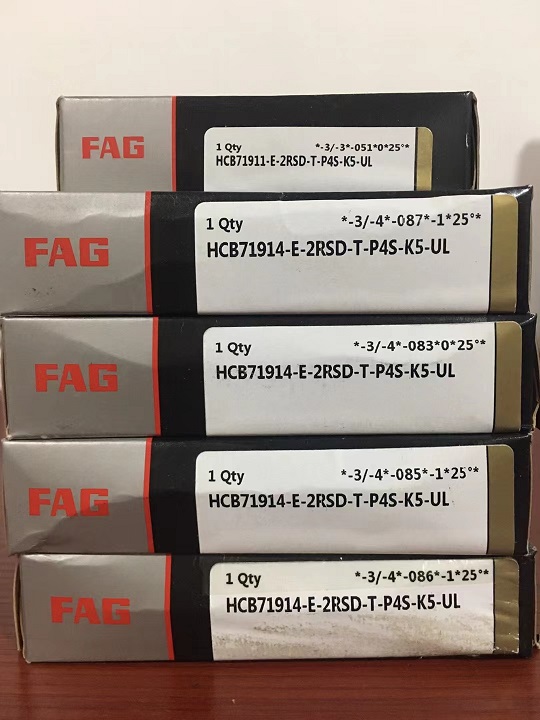

FAG Ball Bearings – Common in high-speed applications like bottling lines.

FAG Roller Bearings – Used in heavy-load systems such as pallet conveyors.

FAG Linear Bearings – Essential for precise straight-line motion in cutting and folding machines.

Benefits of Using FAG Bearings in Packaging

Increased Efficiency – Reduced friction leads to faster production speeds.

Enhanced Durability – High-quality bearings minimize wear and tear.

Lower Maintenance Costs – Reliable bearings decrease downtime and repair expenses.

FAG Bearings are indispensable in the packaging industry, contributing to automation, precision, and productivity. As packaging technology advances, the demand for high-performance bearings will continue to grow, driving further innovation in the field.Need FAG bearings,contact us freely.